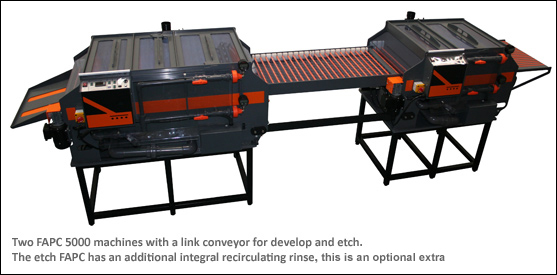

Conveyorized Spray Processing Machines FAPC5000

The new FAPC Conveyorised Processing Modules are designed to work with the latest developing, etching and stripping chemistry for the manufacture of Printed Circuits, Metal Signs and Metal‘chemical milled’ components. The FAPC 5000 panels up to 500mm wide.

The machines are manufactured in our factory in Cambridge using the very latest CNC fabrication and plastic welding techniques. We have been selling conveyor units for over 20 years and that experience has been used to design and manufacture a machine with many unique features to provide a fast, efficient and accurate spray conveyor that is easy to install, maintain and use.

The units will accommodate panels 500mm wide through the process chamber before passing through a void chamber and water rinse section to completely clean the processed panel. A catch tray is included and the stand is an optional extra.

| Description | Chemical spray processor including mains water rinse | |||

| Process chamber Water rinse chamber |

450mm 280mm |

|||

| Spray bars - top | 4 process chamber, 1 rinse chamber | |||

| Spray bars - bottom | 4 process chamber, 1 rinse chamber | |||

| Nozzle type | Poly v-jet – ¼ turn removable | |||

| FAPC 5000 | ||||

| Nozzles per tube | 5 + 6 for Process, 6 for Rinse | |||

| Nozzles | Precision mounted for perfect alignment.In adjustable, compact manifold systems. | |||

| Flow Control / Pressure control | Adjustable over full range Top & Bottom | |||

| Flow Safety | Closed Valve Protection System (Avoid overheating & bursting) | |||

| Re-circulating pump | 0.55kW magnetic coupled drive, running in free flow Air system to avoid overheat | |||

| Process Chamber | Safety Interlock Lid | |||

| Conveyor drive | Worm and wheel | |||

| Pinch Rollers | Precision finish, balanced, high grip for precision control and de-wetting. | |||

| Self Adjusting Liquid Baffles | Controls Liquids on process and rinse, loading and Exit ports.Avoids chemical loss and ‘after wetting’. | |||

| Conveyor Speed Control | High Torque. AC Drive Motor system driven by a precision Inverter with digital read-outs, for precise operator reference | |||

| Speed range | 45mm – 1.6 metres / minute | |||

| Temperature range | Ambient to 50°C ± 1°C | |||

| Temperature Controller | Digital | |||

| Cooling | Available as Factory built optional extra (not usually required) | |||

| FAPC 5000 | ||||

|

50 litres 36 litres |

|||

| Liquid low level sensors | For Heater and Pump | |||

| Over Temp Protection | Manual reset | |||

| Construction materials | P.V.C. EPDM, Quartz Glass | |||

| Filter Systems | Cross Flow Sediment Baffle System. Line Strainer Filtration System and Mesh Screen Filtration System. |

|||

| Voltage | 220/240v 50Hz (13A Plug) | |||

| FAPC 5000 | ||||

|

670mm 870mm 1430mm |

|||

| Mounting Frame | (Optional extra) | |||

| Exit Catch Tray | Standard | |||

| Lifting Facilities | 4 Easy-to-lift Points on Corners | |||

| Negative Pressure Port | Standard to stop the escape of any airborne chemistry | |||

| Negative Pressure Kit | Optional Extra | |||

| Order Code | Description | Price | QTY |